TIG Welding Guide for 316L Stainless Steel 90° Elbow Fittings in Semiconductor Vacuum Piping

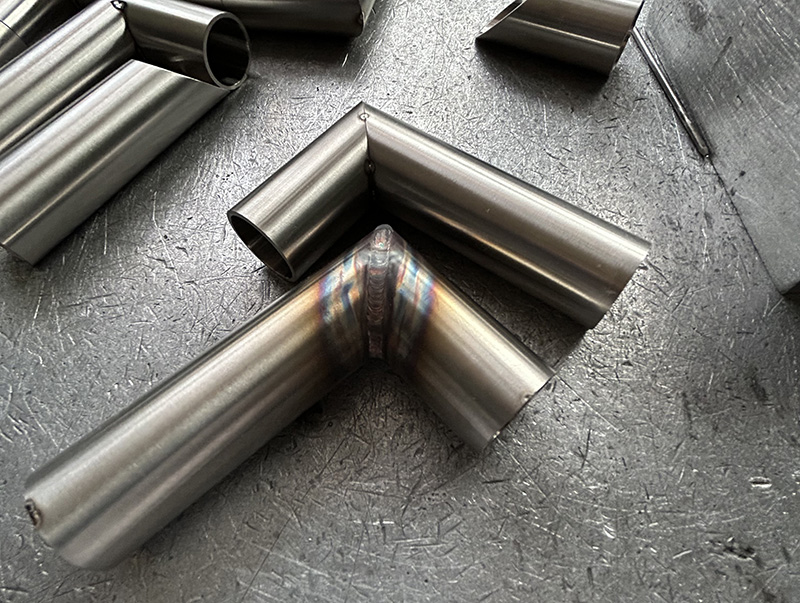

This document outlines the autogenous TIG welding workflow and process parameters for 316L stainless-steel 90° elbow fittings (25.4 mm × 1.68 mm) typically used in semiconductor vacuum systems. The procedure is based on the Panasonic YC-400TX4 TIG welding machine and is specifically optimized for elbows that consist of an outer sharp corner and an inner […]